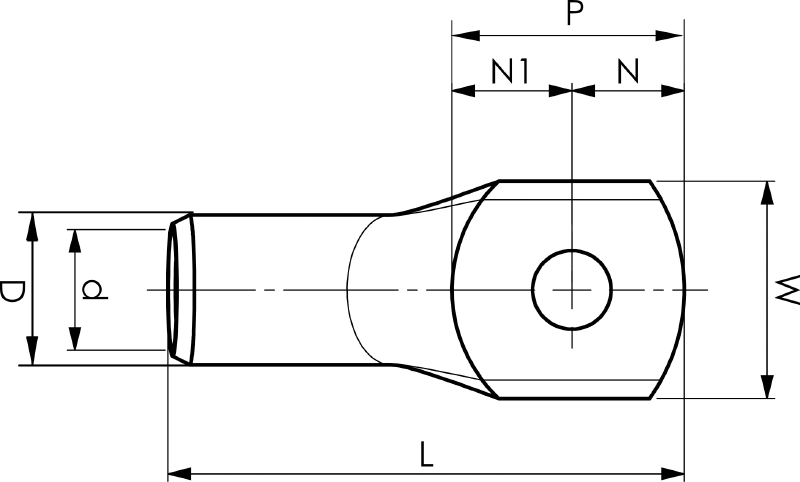

Tube terminals 0.75 - 10 mm²

Material: Cu 99.95%, tin plated Cu/Sn. For multi-stranded (class 5) and stranded (class 2) Cu conductors. UL approved (1.5 -10 mm²). Examples of palm marking KR: 10 10 10 = mm² 10 = Palm hole for M10

Articles

| Cat. No. | Area mm² | CuAWG/MCM | d | D | N | N1 | L | W | s | t | Screw | Die no. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KR0,75-3 | 0,75 | 18 | 1.3 | 2,8 | 3.2 | 3.8 | 17 | 6 | 7.5 | 0.85 | M3 | |

| KR0,75-4 | 0,75 | 18 | 1.3 | 2,8 | 3.2 | 3.5 | 17 | 6 | 7.5 | 0.8 | M4 | |

| KR1,5-3 | 1,5 | 16 | 1.8 | 3,3 | 3.4 | 3.6 | 16 | 6.5 | 7.5 | 1 | M3 | |

| KR1,5-4 | 1,5 | 16 | 1.8 | 3,3 | 4.2 | 3.8 | 17 | 6.5 | 7.5 | 0.9 | M4 | |

| KR1,5-5 | 1,5 | 16 | 1.8 | 3.3 | 4.8 | 4.7 | 18 | 7.5 | 7.5 | 0.85 | M5 | |

| KR2,5-3 | 2,5 | 14 | 2.3 | 4.2 | 3.5 | 4.1 | 17 | 7.5 | 7 | 1.3 | M3 | |

| KR2,5-4 | 2,5 | 14 | 2.3 | 4.2 | 4.2 | 4.1 | 18 | 7.5 | 7 | 1.3 | M4 | |

| KR2,5-5 | 2,5 | 14 | 2.3 | 4.2 | 4.8 | 4.8 | 19 | 8.5 | 7 | 1.1 | M5 | |

| KR2,5-6 | 2,5 | 14 | 2.4 | 4.2 | 5.1 | 5.8 | 19 | 8.5 | 7 | 1.1 | M6 | |

| KR4-3 | 4 | 12 | 3 | 5 | 4.2 | 5.8 | 21 | 8.5 | 8.5 | 1.5 | M3 | |

| KR4-4 | 4 | 12 | 3 | 5 | 4.2 | 5.8 | 22 | 8.5 | 8.5 | 1.5 | M4 | |

| KR4-5 | 4 | 12 | 3 | 5 | 4.8 | 5.2 | 22 | 9 | 8.5 | 1.5 | M5 | |

| KR4-6 | 4 | 12 | 3 | 5 | 5 | 7 | 23 | 9.9 | 8.5 | 1.3 | M6 | |

| KR6-4 | 6 | 101 | 4 | 6 | 4 | 6 | 22 | 9.5 | 8.5 | 1.7 | M4 | |

| KR6-5 | 6 | 101 | 4 | 6 | 5 | 6 | 22 | 9.5 | 8.5 | 1.7 | M5 | |

| KR6-6 | 6 | 101 | 4 | 6 | 5.5 | 6.5 | 23 | 9.9 | 8.5 | 1.6 | M6 | |

| KR6-8 | 6 | 101 | 4 | 6 | 7 | 10 | 30 | 13 | 8.5 | 1.2 | M8 | |

| KR10-4 | 10 | 8 | 5 | 8 | 6 | 8 | 29 | 11.5 | 11 | 2.9 | M4 | 8 |

| KR10-5 | 10 | 8 | 5 | 8 | 6 | 7.5 | 29 | 11.5 | 11 | 2.9 | M5 | 8 |

| KR10-6 | 10 | 8 | 5 | 8 | 6 | 7.5 | 29 | 11.5 | 11 | 3 | M6 | 8 |

| KR10-8 | 10 | 8 | 5 | 8 | 7.5 | 8.5 | 33 | 13.5 | 11 | 2.3 | M8 | 8 |

| KR10-10 | 10 | 8 | 5 | 8 | 8 | 10 | 34 | 16 | 11 | 2 | M10 | 8 |

| KR10-12 | 10 | 8 | 5 | 8 | 10 | 13.5 | 41 | 18.5 | 11 | 1.7 | M12 | 8 |

- s = strip length

- t = palm thickness