Frequently asked questions

Here, you can get answers to the most frequently asked questions.

Are you unable to find the help you need?

Contact us directly at support@elpress.se

Order, Payment and Invoices

You can find our products at well-stocked electric wholesalers.

You are also welcome to contact our order office at order@elpress.se or +46 612 71 71 70 and they will help you.

Contact our order office, order@elpress.se, tel +46 612 71 71 70.

Yes, of course, e-mail it to supplierinvoice@elpress.se.

Questions about Products

You should use bright zinc plated screws and nuts with a strength grade of at least 8.8 or property class 70 (ISO 3506) for stainless steel screws and nuts.

Tightening torque

| Screw | FZB, (8.8) Nm | -stainless steel class 70 Nm | stainless steel class 80 Nm |

| M5 | 5 | 4 | 5 |

| M6 | 9 | 7 | 9 |

| M8 | 21 | 17 | 22 |

| M10 | 41 | 33 | 44 |

| M12 | 70 | 57 | 75 |

| M16 | 170 | 140 | 180 |

| M20 | 340 | 270 | 350 |

System Elpress uses marking on the tube for copper connectors. Looking at a KRF or KSF70, the number 17 are engraved on the neck, indicating that one should use crimping dies with number 17, such as B17, 13B17 TB8-17.

When looking for the right tool to crimp a 95 mm² AK/AS aluminium or aluminium side on a AlCu terminal, it says on the sleeve which tools are to be used. On an AS95, it says ALU95-R13-P25, which means that if a V250 is used, matrix P25M and punch P25 should be used together with matrix holder V2521. R13 stands for a round shape being made if one uses a sector-shaped cable and then the following are used: matrix holder V2531, matrix R13MR, punch R13DR and punch holder V2540.

Pre insulated terminals and tools almost solely use colours that indicate the area for the connector.

It is a misunderstanding to speak about how many Amps a terminal lug or through connector can handle; what is interesting is how high the temperature is in the connection/cable. In the dimensioning of a connection, consideration is taken to the ambient temperature and how much cooling capacity there is to the connection. Our terminals are designed so that when they are crimped according to Elpress’ instructions, they can handle as much load as a power cable as per IEC61238.

No, we see this as a negative as it introduces another contact surface, which can lead to higher resistance. One can advantageously use Vaseline on the contact surfaces after cleaning off the contact surface on the aluminium rail.

Yes, this can be done and should normally be done. The connection point should be protected from weather and wind, and the humidity or other pollutants in the air may not be high so as to cause deposits in connections that can form an electrolyte.

You can contact our sales department at order@elpress.se and we will help you.

Too many screw joints are done incorrectly.

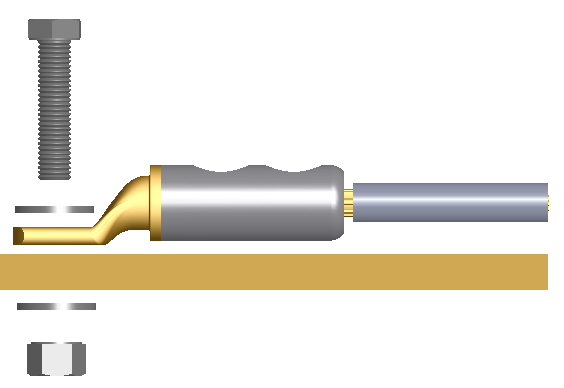

Expressions like “I tighten it until it feels good and I don’t need a washer” are not good. It has been shown that the use of a torque wrench provides a percentage error of a few per cent while “I tighten it until it feels good” provides a significantly larger percentage error. Our recommendations are to:

- Always us a torque wrench to be certain the right torque is achieved. Make sure it is calibrated as regular intervals according to the supplier’s instructions.

- Use the torque according to the Elpress catalogue or the screw manufacturer’s regulations.

- Always use a plain washer to reduce the friction against the contact surface and hole edge pressure.

- Assemble as shown

- For special applications, a spring washer as per DIN 6796 can be used together with a plain washer to further increase the force.

Elpress certificates for the environment can be found here: Environmental certificates

Elpress certificates for quality can be found here: Quality certificates

Elpress standard products for Cu connections are UL and DNV approved, see Cu connections.

Elpress end terminals are CSA certified.

Yes, it is right.

Elpress Cu connections of type KRF/KSF are designed to be used with both stranded (IEC 60228 class 2) and flexible cables (IEC 60228 class 5). In crimping with Elpress tools, the difference in physical area will be evened out as the air is pressed out, however. The “gap” that one initially sees is accordingly an optical problem – it may seem strange, but it is right!

General questions

Elpress provides a one or two-year warranty, which does not apply to damage arising from normal wear.

Go to the Elpress website and click on the Service menu and at the bottom of the page, there are documents that can be downloaded. Download return note and enter the information with what you want done or what is wrong with the product; the form also has the address for where to send the tool.

Yes, tools can be rented from us. E-mail our service department at service@elpress.se or call the service department at 0612-71 71 81.

Read more on our Service page.

Yes. We actively work with certifications and other quality assurance work.

Follow the links below to read more about our quality assurance work.

Knowledge provides qualityWe actively work for a better environment