AlCu terminals

Elpress AlCu terminals for Al conductors are made of solid material.

We produce the terminals with friction welding, which means that aluminium is joined with copper. This is done when aluminium is rotated towards copper under pressure and it is the method that provides the best bond between Al and Cu. We produce AlCu terminals of type AKK, AKS and AKP, but also largely customised terminals (also larger than 1200 mm2).

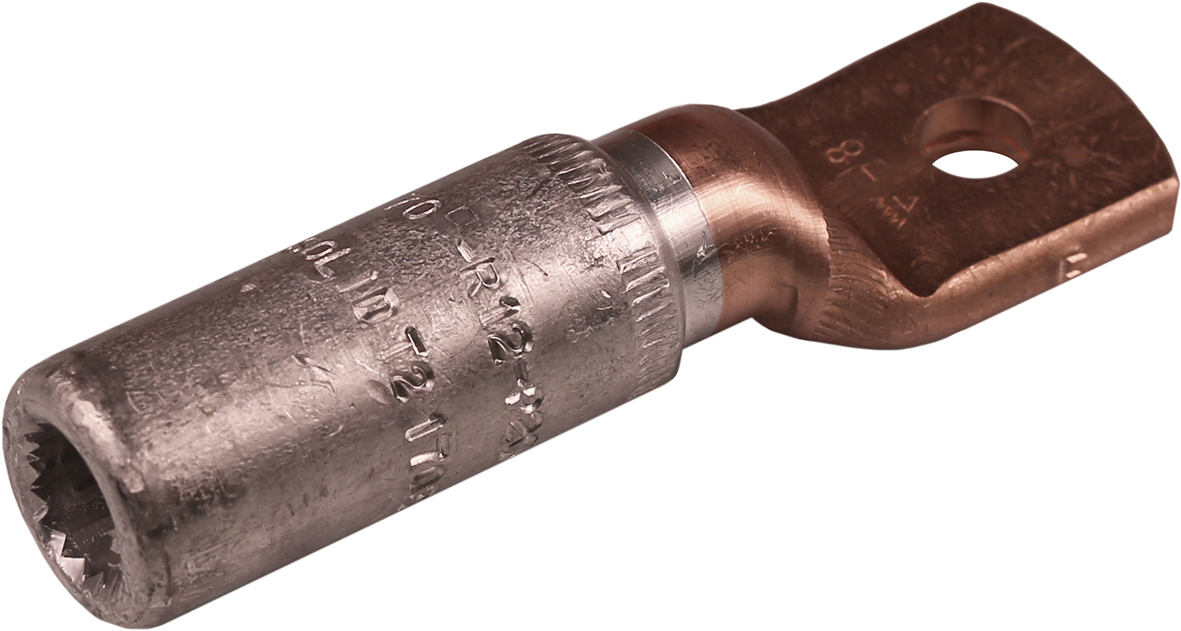

- Terminals of type AKK are used at the end of an Al conductor for connection to a Cu bus bar.

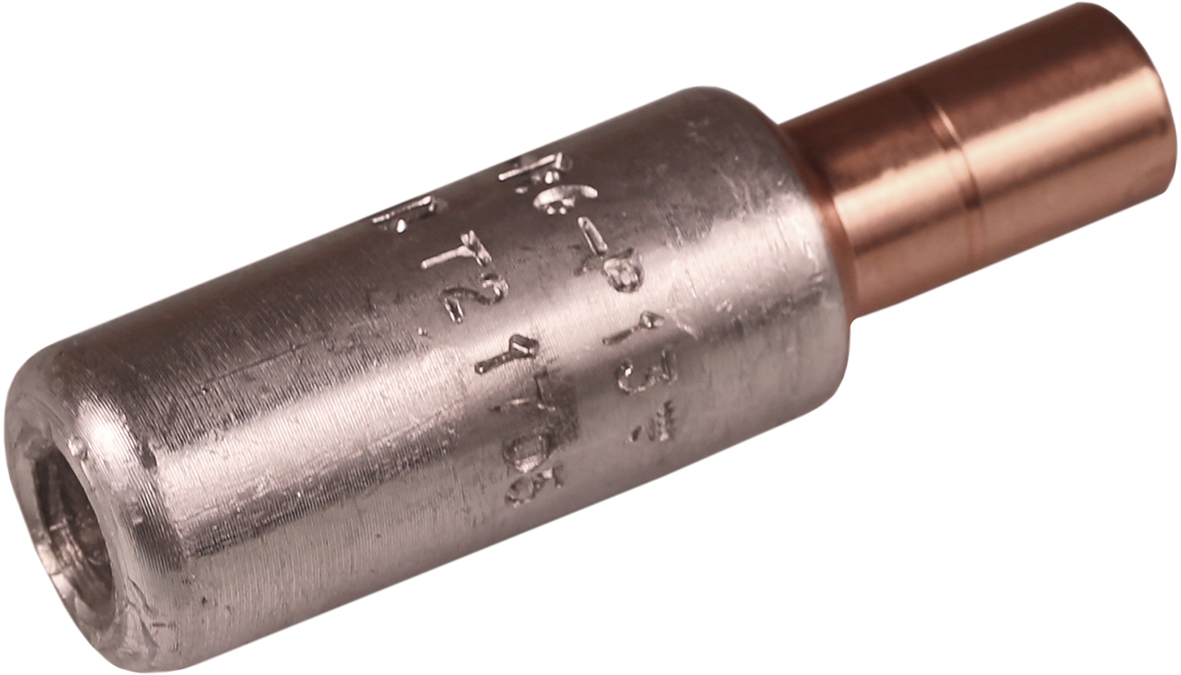

- Through connectors of type AKS are used for jointing of Al conductors to Cu conductors.

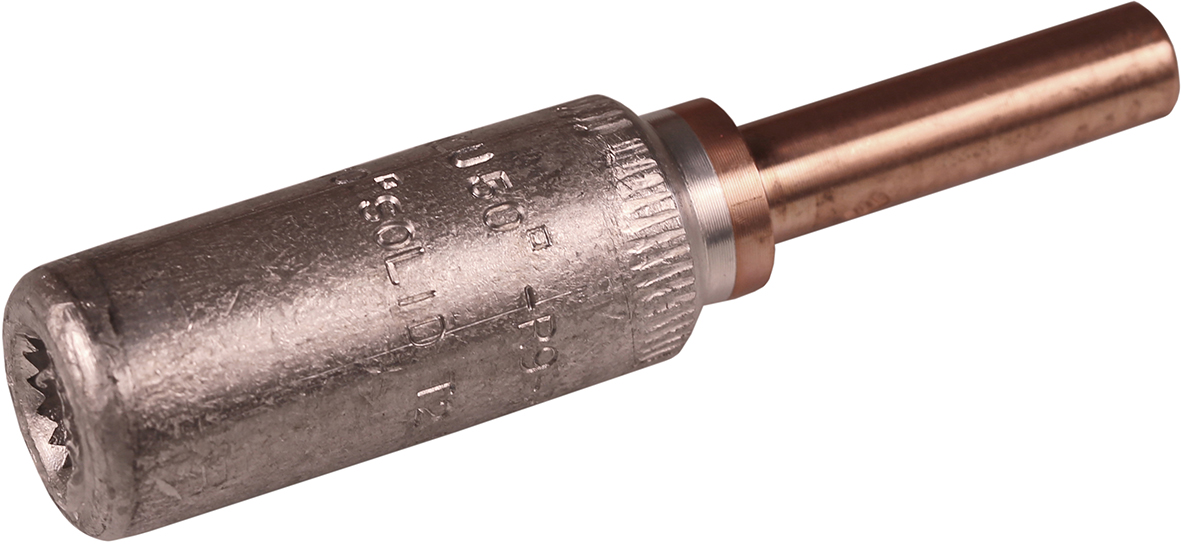

- Pin sleeves of type AKP are made for connection of Al conductors to apparatus with connections of copper.

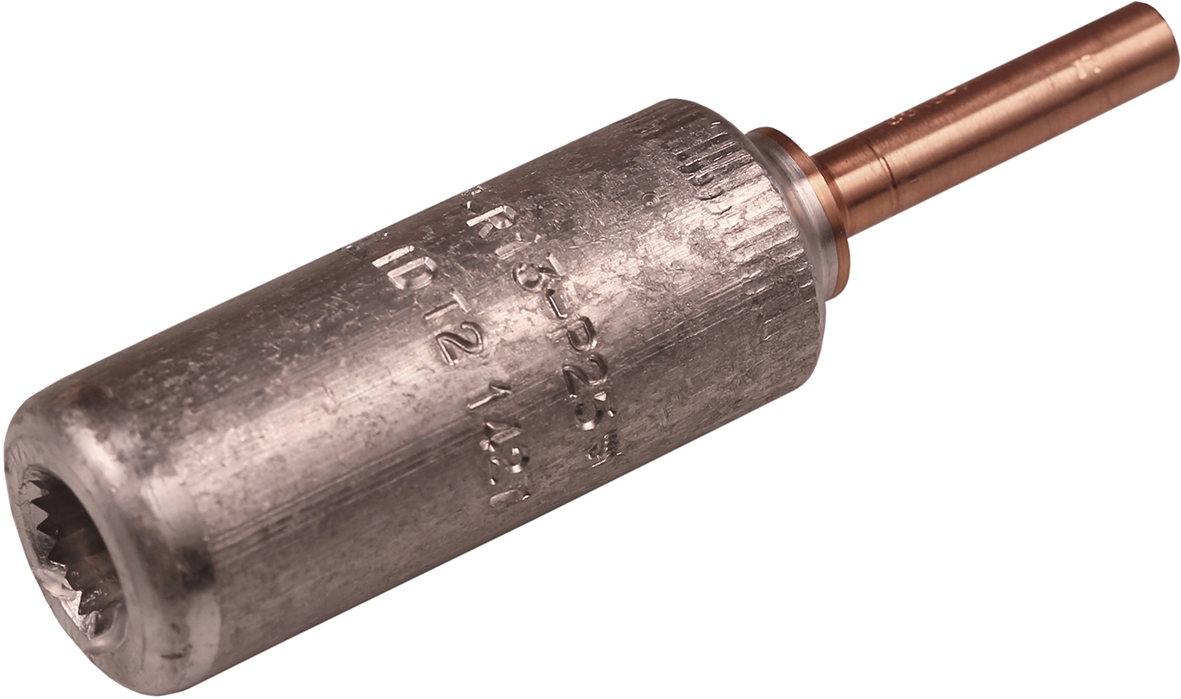

- Transition through connectors of type AKS-10S are used for jointing stranded Al conductors to solid Cu conductors 10 mm² (e.g. Excel, Excelett)

Marking and number of crimps

The AlCu terminals are marked with logotype, conductor area for stranded and solid conductors and reference to round crimping tool and crimping tool in the Elpress product range. On the through connectors, a tool reference is also given for hexagonal crimping of copper.

When an adequate crimping is done with the right tool, Elpress' dies makes an impression on the sleeve so that all connections can be checked afterwards.

In the tools, there is a built-in full closure system that ensures that the entire crimping process is completed - a prerequisite for professional and quality-assured work. When crimping, two crimps are always done on the Al part and normally 1-2 crimps on the Cu part. Check the number of crimps recommended on the package label before crimping is done.

Customised products

Upon requests for variants in hole arrangement, the size of the connection flag and the like, we make variants of cable clips. Read more on our page about Consulting.

Products

Aluminium-copper terminals 16 - 1200 mm²

Used for connection of Al conductors for apparatus outlets and busbars of Cu.Two crimps are needed - For crimp sequence, see image.

Aluminium-copper pin sockets 16 - 300 mm²

Used for connection of Al conductors to apparatus with copper connectors.Two crimps are needed - For crimp sequence, see image.

Through connectors of aluminium 16 - 95 mm² to solid copper 10 mm²

Transition joints from stranded Al conductors to solid Cu conductors 10 mm² / 8 AWG (e.g. Excel, Excelett). Two crimps are needed for both Al (crimp sequence see image) and Cu.

Aluminium-copper through connectors 16 - 400 mm²

Connector from Al conductor to Cu conductor.Stranded/solid Al conductors, stranded/multi-stranded Cu conductors. For multi-stranded Cu conductors, contact crimping using the Dual system is recommended.Two crimps are required for Al (see image) normally one for Cu.When hexagonally crimping the Cu part, the dies are placed between the marking groove and the outer edge.

System Elpress

System Elpress symbolises Elpress’ guiding principles of safety and quality. These principles are reflected in our certified solutions, training courses and preventive maintenance in the form of service.